Products on sale

ASTM A335 P5 1.7362 X11CrMo5 Alloy bend mild steel pipe bending steel 5D 10D elbow bend pipe

描述

Piping systems transport fluids and gases across various systems. A Pipe Bend is used to change the direction of flow within the system. These bends help in transmission of these fluids and gases across long distances. They have a minimum bending radius of about 1.5 times the pipe radius. A hot induction bend follows a controlled bending process wherein pipes are bend using a high frequency induced power. The bending radius in these bends is between 3D to 10D, and the angles range up to 180°. In the miter bend, pipe ends are cut at an angle and joined together. These bends are available by either joining 2 pipes of 45° together or 3 pipes of 22.5° together giving, them a 90° bend. SS Mitered Pipe Bend is designed with high corrosion and oxidation resistance properties. These bends can be easily cleaned and possess a long service life. The ASME B16.49 Pipe Bend is used for various applications in shipbuilding, commercial vehicles, industrial systems, transportation of fluids and gases, architecture, automotive industries, and so on.

The ASTM A860 WPHY42 Seamless Bend possesses superior strength and excellent mechanical properties. These bends are produced without the requirements of any seams or welds. The ASTM A234 WPB U Bend is used in various plumbing systems. These bends contain water and prevent sewer gases from passing through the pipes and entering leaving spaces. Apart from this, they prevent clogging from taking place within the system. In the ASTM A403 WP304 Long Radius Bend, the radius of curvature is more than 1.5 times the nominal size. These bends allow less friction resistance between fluids and show lower pressure drops. The Stainless Steel Short Radius Bends are preferred in applications where there is less space available. These low-cost bends have a radius of curvature, which, is 1.0 times the nominal size of the pipe. We are the pipe bend manufacturer who can customize all our products as per your requirements in different shapes and sizes.

The Carbon Steel 3D Pipe Bend allows the bending of pipes without any collapsing or crippling of the existing pipe. These bends possess a good concentration of carbon which gives them enhanced strength and excellent properties. API 5L 5D Pipe Bend is designed with a smooth finish. They have high working efficiency and can bend in various angles and radiuses. The Stainless Steel Return Bend is used to change the direction of flow by 180 degrees. These bends are preferred in connecting parallel pipes together to avoid sedimentation or blockage due to some elements. The Carbon Steel J Bend is known for its excellent performance and structure in various systems. These bends are fabricated in a J shape and are mostly used in draining water from piping systems. An Alloy Steel Flange Bend is available in different schedules ranging from SCH 5 to SCH 160. These bends are coated, galvanized, phosphated, etc. The main difference between a pipe bend and the ASTM A106B Elbow is that the elbow is shorter than a bend. Apart from this, elbows are mostly designed with either a 45 or 90 degrees radius.

Hot Induction Bend Specification

ASTM A106B SR Elbow, A420 WPL6 Long Radius Elbow and A860 WPHY42 Miter Bend manufacturer in Mumbai, check sizes and bending radius

Computerized systems to design Hot Induction Bend:

Computerized systems and advanced programs allow our technical department to design and optimize the Hot Induction Bend & other special fittings and flanges respecting all customer’ specifications and applications.

Hot Induction Bend Design in accordance with recognized Rules.

Calculation in complete accordance with ASME, DIN, EN and STOOMWEZEN rules.

Pipe Bend Grades available

Manufacturer of API 5L Grade B Pipe Bend in all radius such as 3D 4D, 5D, 1.5D, 2D, 6D, 7D, 8D, 9D, 10D in LR/ Short Radius in Mumbai

Nickel Alloy Hot Induction Bend

ASTM / ASME SB 336 UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Copper Alloy Steel Hot Induction Bend

ASTM / ASME SB 111 UNS NO.C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 , C 71500

ASTM / ASME SB 466 UNS NO.C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Stainless Steel Hot Induction Bend

ASTM / ASME SA 403 GR WP “S” / “W” / ” WX” 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H

Duplex Steel Hot Induction Bend

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760

Carbon Steel Hot Induction Bend

ASTM / ASME A 234 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Alloy Steel Hot Induction Bend

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91

Types : Forged Elbow, Forged Tee, Forged Reducer, Forged Return Bends, Forged Stub-Ends, Forged Cap, Forged Collar, Forged Cross, Forged Insert etc.

Hot Induction Bend Size : 1/2” NB TO 24” NB.

Hot Induction Bend Material

Seamless Fittings – 1/2” to 24” Welded Fittings – 1/2” to 60”

Elbow LR & SR Bend, Crosses, Stub-End, Tee, Reducer, Flange, End Cap

Long Radius Bends, Long Radius Piggable Bends, Induction Pipe Bending Bends

Long Radius Carbon Steel Bends, Long Radius High Yield Carbon Steel Bends

Long Radius Bends R-2D, R-3D, R-5D, R-6D, R-8D upto 22D

Long Radius Piggable Bends R-2D, R-3D, R-5D, R-6D, R-8D upto 22D

Hot Induction Long Radius Bends R-2D, R-3D, R-5D, R-6D, R-8D upto 22D

API-5L Hot Induction Long Radius Bends R-2D, R-3D, R-5D, R-6D, R-8D upto 22D

Induction Pipe Bending Bends 2D, 3D, 5D, 6D, 8D upto 22D

Induction Long Radius Pipe Bending Bends API 5L X42, X46, X52, X56, X60, X65, X70

Induction Long Radius Pipe Bending Bends API5LX-42, X-46, X-52, X-56, X-60, X-65, X-70

Long Radius Bends 30 Deg., 45 Deg., 60 Deg., 90 Deg., 180 Deg., 360 Deg. upto 60″ Diameter

Long Radius Bends in API 5L X42, API 5L X46, API 5L X52, API 5L X56, API 5L Grade B

Long Radius Bends in API 5L X60, API 5L X65, API 5L X70, API 5L Grade-B

Long Radius Bends in API 5L X-42, API 5L X-46, API 5L X-52, API 5L X-56, API 5L Grade B

Long Radius Bends in API 5L X-60, API 5L X-65, API 5L X-70, API 5L Grade-B

SA-234 WPB, WPC, WP1, WP5, WP7, WP9, WP11CL7, WP12CL1, WP22, WP91

ASTM A-860 WPHY-42, WPHY-46, WPHY-52, WPHY-56, WPHY-60, WPHY-65, WPHY-70

ASTM A-860 WPHY42, WPHY46, WPHY52, WPHY56, WPHY60, WPHY65, WPHY70

MSS SP75 WPHY 42, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

MSS SP75 WPHY42, WPHY46, WPHY52, WPHY56, WPHY60, WPHY65, WPHY70

MSS-SP-75 WPHY42, WPHY46, WPHY52, WPHY56, WHPY60, WHPY65, WPHY70

MSS-SP-75 WPHY 42, WPHY 46, WPHY 52, WPHY 56, WHPY 60, WHPY 65, WPHY 70

MSS-SP-75 WPHY-42, WPHY-46, WPHY-52, WPHY-56, WHPY-60, WHPY-65, WPHY-70

MSS SP75 WPHY42, WPHY46, WPHY52, WPHY56, WHPY60, WHPY65, WPHY70

MSS SP75 WPHY 42, WPHY 46, WPHY 52, WPHY 56, WHPY 60, WHPY 65, WPHY 70

MSSSP75 WPHY-42, WPHY-46, WPHY-52, WPHY-56, WHPY-60, WHPY-65, WPHY-70

ASTM A-234 WPB, ASTM A234 WPC, ASTM A234 WPB Seamless, ASTM A234 WPC Seamless

ASTM A-234 WP1, WP11 CL1, WP11 CL3, WP12 CL1, WP22 CL1, WP22 CL3

ASTM A-234 WP5 CL1, WP5 CL3, WP9 CL1, WP9 CL3, WP91

ASTM A-403 WP304, 304L, 304H, 310S, 316, 316L, 316H, 321, 321H, 347, 347H, 317, 317L

ASTM A-420 WPL3, WPL6, WPL8, WPL9

ASTM A-182 F304, F304L, F304H, F310S, F316, F316L, F316H, F321, F321H, F347, F347H, F348

ASTM A-182 F1, F11, F12, F22, F5, F9, F91, F92

ASTM A-182 F-1, F-11, F-12, F-22, F-5, F-9, F-91, F-92

ASTM A-694 F-42, ASTM A694 F-46, ASTM A694 F-52, ASTM A694 F-56

ASTM A-694 F-60, ASTM A694 F-65, ASTM A694 F-70, ASTM A694 F-80

SAE / AISI Grade 1008, 1010, 1018, 1020, 1025, 1026, 1040, 1045, 1050, 4130, 4140, 4150, 4340

AISI-4130 L-80 according to API-5CT, 75KSI according to API-6A Quenched / Hardened & Tempered

SAE-4130 L-80 according to API-5CT, 75KSI according to API-6A Quenched / Hardened & Tempered

AISI-4140 L-80, P-110 according to API-5CT, API6A, NACE MR-01-75 Quenched / Hardened & Tempered

SAE-4140 L-80, P-110 according to API-5CT, API6A, NACE MR-01-75 Quenched / Hardened & Tempered

Duplex 2205, Duplex SAF 2205, Duplex SAF2205, Duplex UNS S31803, Din 1.4462 EN 10088 F51

Duplex ASTM A182 Grade F60 / ASME SA182 Grade F60 NACE & Norsok Approved

Duplex SAF2205 SANMAC, URANUS 45N, PREN=33, PREN=34, PREN=35, PREN=36 DIN 1.4462

Duplex-2205 UNS S31803 / UNS S32205 DIN-1.4462 EN 10088-3 PREN = 33, PREN = 34, PREN = 35

Super Duplex 2507, Super Duplex SAF 2507, Super Duplex SAF-2507, Super Duplex UNS S32750 F53

Super Duplex SAF 2507 UNS S32750 DIN 1.4410 EN-10088 URANUS 47N(+) PREN=41 Minimum

Super Duplex UNS S32760 F-55 ASTM A182 F55 SA182 F-55 DIN 1.4501 UNS 32760 F55

Types of ASTM A860 WPHY42 Seamless Bend

Specialized manufacturer of Alloy Steel Flange Bend and Carbon Steel J Bend in Mumbai, view Induction Bending Process, Dimensions and price list

-

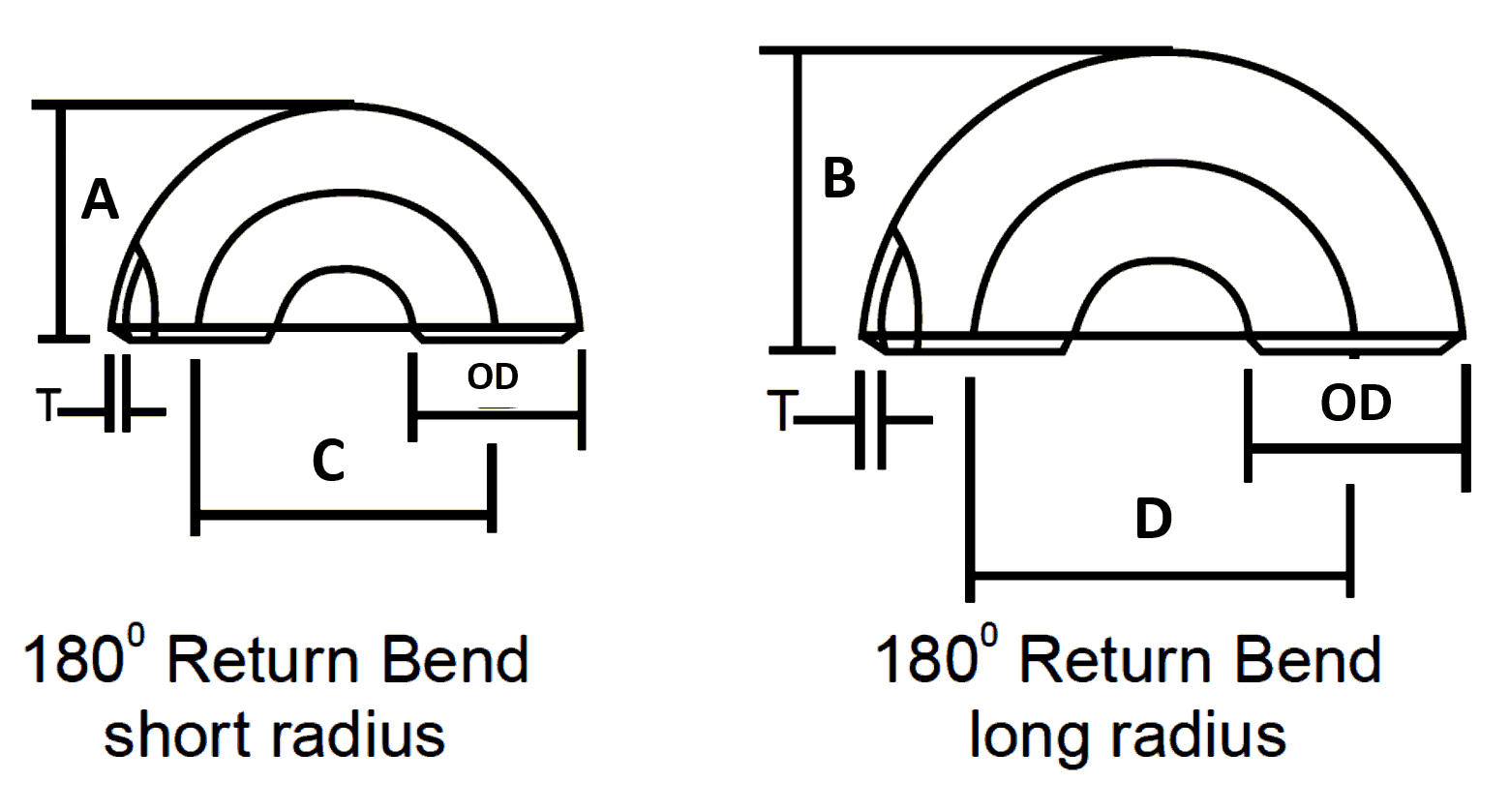

Long Radius Pipe Bends & Return Dimensions (Pipe U Bends)

- For Wrought Product (WP) Dimension is covered in

- ASME B16.9- which is standard for Factory-made Wrought Butt-welding Fittings for size NPS 1⁄₂ to NPS 48” and

- And B16.28- which is standard for Wrought Steel Butt-Welding Short Radius Elbows and Returns for size NPS 1⁄₂ to NPS 24”

Nominal Pipe Size Outside Diameter Back to Face Center to Center Inch. OD A B C D 1/2 21.3 48 – 76 – 3/4 26.7 43 – 57 – 1 33.4 56 41 76 51 1 1/4 42.2 70 52 95 64 1 1/2 48.3 83 62 114 76 2 60.3 106 81 152 102 2 1/2 73 132 100 191 127 3 88.9 159 121 229 152 3 1/2 101.6 184 140 267 178 4 114.3 210 159 305 203 5 141.3 262 197 381 254 6 168.3 313 237 457 305 8 219.1 414 313 610 406 10 273.1 518 391 762 508 12 323.9 619 467 914 610 14 355.6 711 533 1067 711 16 406.4 813 610 1219 813 18 457.2 914 686 1372 914 20 508 1016 762 1524 1016 22 559 1118 838 1676 1118 24 610 1219 914 1829 1219 All dimensions are in mm Pipe Fittings Dimensions Tolerance as per ASME B16.9

Pipe FIttings Quiz – Test yourself, Take This Quiz

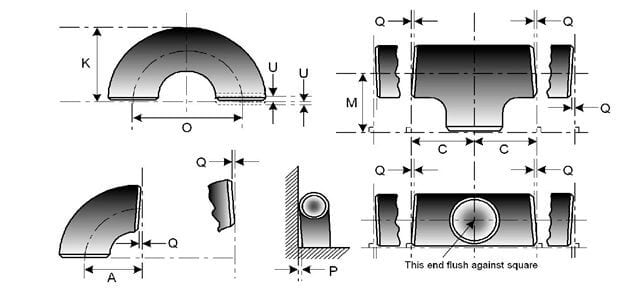

NOMINAL PIPE SIZE ALL FITTINGS ALL FITTINGS ALL FITTINGS ELBOWS AND TEES 180 DEG RETURN BENDS 180 DEG RETURN BENDS 180 DEG RETURN BENDS REDUCERS CAPS NPS O.D. at Bevel (1), (2) I.D. at End

(1), (3), (4)Wall Thickness (3) Centre-to-End Dimension A,B,C,M Centre-to-Centre O Back-to-Face K Alignment of Ends U Overall Length H Overall Length E ½ to 2½ 0.06

-0.030.03 Not less than 87.5% of nominal thickness 0.06 0.25 0.25 0.03 0.06 0.12 3 to 3 ½ 0.06 0.06 0.06 0.25 0.25 0.03 0.06 0.12 4 0.06 0.06 0.06 0.25 0.25 0.03 0.06 0.12 5 to 8 0.09

-0.060.06 0.06 0.25 0.25 0.03 0.06 0.25 10 to 18 0.16

-0.120.12 0.09 0.38 0.25 0.06 0.09 0.25 20 to 24 0.25

-0.190.19 0.09 0.38 0.25 0.06 0.09 0.25 26 to 30 0.25

-0.190.19 0.12 … … … 0.19 0.38 32 to 48 0.25

-0.190.19 0.19 … … … 0.19 0.38 NOMINAL PIPE SIZE NPS ANGULARITY TOLERANCES ANGULARITY TOLERANCES ALL DIMENSIONS ARE GIVEN IN INCHES. TOLERANCES ARE EQUAL PLUS AND MINUS EXCEPT AS NOTED. Off Angle Q Off Plane P (1) Out-of-round is the sum of absolute values of plus and minus tolerance.

(2) This tolerance may not apply in localized areas of formed fittings where increased wall thickness is required to meet design requirements of ASME B16.9.

(3) The inside diameter and the nominal wall thicknesses at ends are to be specified by the purchaser.

(4) Unless otherwise specified by the purchaser, these tolerances apply to the nominal inside diameter, which equals the difference between the nominal outside diameter and twice the nominal wall thickness.½ to 4 0.03 0.06 5 to 8 0.06 0.12 10 to 12 0.09 0.19 14 to 16 0.09 0.25 18 to 24 0.12 0.38 26 to 30 0.19 0.38 32 to 42 0.19 0.50 44 to 48 0.18 0.75 - For Wrought Product (WP) Dimension is covered in