Products on sale

3000# 1/8″-2″ ASME B16.11 ASTM B564 Hastelloy B2 UNS N10665 Alloy B2 Threaded Street Elbow

描述

Forged Pipe fittings offered in different choices such as elbow, bushing, tee, coupling, nipple and union. It is available in different size, structure and class with different materials such as Stainless steel, duplex steel, alloy steel and carbon steel. JF engineering is the ebst supplier of 90 Degree elbow forged fittings that are designed under the expert guidance.

Forged Pipe fittings offered in different choices such as elbow, bushing, tee, coupling, nipple and union. It is available in different size, structure and class with different materials such as Stainless steel, duplex steel, alloy steel and carbon steel. JF engineering is the ebst supplier of 90 Degree elbow forged fittings that are designed under the expert guidance. We are highly experienced company in ANSI/ASME B16.11 forged fittings and ensure quality of each product.

90 degree elbow has varieties of features such as reliability, durability and dimensional precision. There are lots of advantages of this forged elbow that are easy to install, rugged and corrosion resistant. We are involved in providing a widespread range of forged elbows in different sizes and thicknesses. We are the best in offering different types of elbows such as forged 90 degree elbow, forged 45 deg elbow and forged 180 deg elbow. These elbows used in various industries like chemical industry, sugar mill, fat & fertilizer and distilleries.

90 DEGREE ELBOW

| Size: | 1/2″NB TO 4″NB IN |

| Class: | 3000 LBS, 6000 LBS, 9000 LBS |

| Type: | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Form: | 45 Deg Elbow, 90 Deg Elbow, Forged Elbow, Threaded Elbow, Socket Weld Elbow. |

| Materials: |

Stainless Steel Forged Coupling – SS Forged Coupling Duplex Steel Forged Coupling Carbon Steel Forged Coupling – CS Forged Coupling Low Temperature Carbon Steel Forged Coupling – LTCS Forged Coupling Alloy Steel Forged Coupling – AS Forged Coupling |

| Value Added Service: | Hot Dip Galvanizing Electro polish |

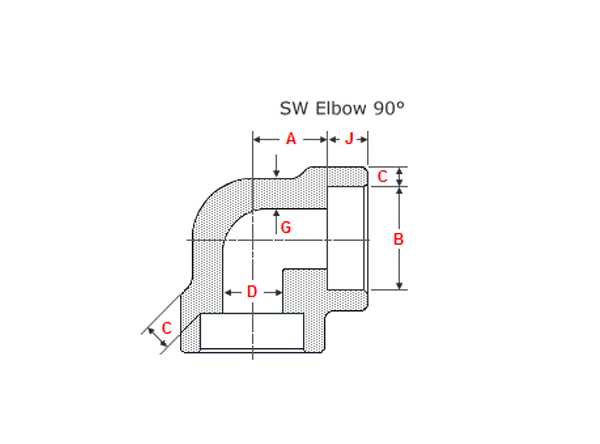

DIMENSIONS 90 DEGREE ELBOW

Dimensions NPS 1/2 to 4 – 90° – Class 3000

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 |

| 1¼ | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 |

| 1½ | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 |

| 2½ | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 |

| NPS | B | J | D | C | G |

| Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| NPS | Center to bottom of socket A | |

| 90° | ||

| 1/2 | 15.5 | |

| 3/4 | 19.5 | |

| 1 | 22 | |

| 1¼ | 27 | |

| 1½ | 32 | |

| 2 | 38 | |

| 2½ | 41.5 | |

| 3 | 57.5 | |

| 4 | 66.5 | |

| NPS | 90° | |

| Center to bottom of socket A | ||

Dimensions NPS 1/2 to 2 – 90° – Class 6000

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

4.80 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

5.55 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

6.35 |

| 1¼ | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

6.35 |

| 1½ | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

7.15 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

8.75 |

| NPS | B | J | D | C | G |

| Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| NPS | Center to bottom of socket A | |

| 90° | ||

| 1/2 | 19.5 | |

| 3/4 | 22.5 | |

| 1 | 27 | |

| 1¼ | 32 | |

| 1½ | 38 | |

| 2 | 41 | |

| NPS | 90° | |

| Center to bottom of socket A | ||

MARKING AND PACKING

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All elbow fittings are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

QUALITY ASSURANCE

At JF Engineering Products LLP all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

TEST CERTIFICATES

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

SHIPPING POLICY

Delivery time and delivery dates are based on the “type and quantity” of steel ordered. Our sales team will provide a delivery schedule when quoting to you. On rare occasions the delivery schedule may change so please check with our sales department when placing any orders.

Orders will be sent out within 2-3 business days, and may take up to 5-10 business days in transit. If ASME B16.9 Forged Elbow is out of stock, orders may take up to 2-4 weeks to ship. J

USES & APPLICATION

Wilson Pipeline Products take immensure pleasure in introducing itself as one of the leading Manufacturer & Exporter of high quality ASME B16.9 Forged Elbow to meet the customer ultimate requirements in the fields of:

| Chemical | Oil Mills | Petrochemical | Mining | Refineries | Construction |

| Fertilizers | Shipbuilding | Power Plant | Steel Plant | Nuclear Power | Offshore |

| Oil & Gas | Defence | Paper | Ports | Breweries | Railway |

| Cement | Engineering Co. | Sugar & | Government Org. etc. |