Products on sale

raised face 200mm class 300 astm a 105n b16.5 carbon steel flange

描述

Flanges are structures, which are used in connecting different piping systems. A Socket Weld Flange is an attachment, which helps in joining pipes in its recessed area. These fittings are used in high-pressure pipes of smaller sizes. The pipes used with this flange are in the range of NPS 2 or lower. The Carbon Steel Socket Weld Flange has a high concentration of carbon in its chemical composition. These flanges don’t require to be beveled in preparation for the welding process. They can also be used instead of threaded flanges. Stainless Steel Socket Weld Flange is designed with superior strength and excellent corrosion resistance properties. These flanges don’t require temporary welds to ensure correct alignment as they can be easily aligned onto the fitting. The SWRF Flange is very versatile and easy to use. This flange comprises of an internal recess on the interior side of the pipe which allows for a smooth flow of fluids and gases. We are the leading

The Raised Face Socket Weld Flange can be identified by the raised surface, which is seen above the bolting area. These flanges help in concentrating more pressure on the raised surface, thereby increasing the pressure containment in the overall flange. Therby the Socket Weld, Raised Face Flange has a stronger seal. These flanges possess a machined smooth finish that is strongly attached to the flange when high pressures are applied to them. In the Flat Face Socket Weld Flange, the ridge or raised face is absent or machined down. These flanges are not affected by any bending pressure when the time to bolt or torquing them arises. For the Reducing Socket Weld Flange, the bore on both ends is made of different sizes. This enables these flanges to connect pipes of different sizes in various piping systems. The A105 Socket Weld Flange along with all our products can be custom designed in different shapes and sizes as per your requirements.

The Socket Weld Pipe Flanges are very reliable and provide a leakproof fitting. These flanges in pipes don’t penetrate to the bore of the pipes when they are welded in place. Apart from this, the construction cost on these flanges is very less. The 316 SS Socket Weld Flange is very strong and possesses high melting points. These flanges also exhibit excellent corrosion resistance properties in stress-induced environments. The cheaper alternative to these flanges is the SS 304 Socket Weld Flange. These flanges possess moderate strength and tolerances. If you have any questions or want to know in detail about our flanges, contact us or visit any of our outlets.

Exporter & suppler of ASTM A105 Carbon Steel Socket Weld Reducing Flange and A350 LF2 SW RF Flange accordance to EN 1092-1, ANSI/ ASA, BS 4504, ASME B16.5 specification

Stainless Steel Socket Weld Flange Specification

Manufacturer of 304/ 316 Stainless Steel Socket Weld Flange and Nickel Alloy Socket Weld Raised Face Flange in RTJ Type and FF/ RF Face

Size: 1/2″ (15 NB) to 48″ (1200NB)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Pressure Ratings: Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc.

Carbon Steel Socket Weld Flanges/ SWRF flanges Flanges: ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8

Stainless Steel Socket Weld Flanges/ SWRF flanges Flanges: ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L

Alloy Steel Socket Weld Flanges/ SWRF flanges Flanges: ASTM A182 F1, F5, F9, F11, F22, F91

Special Alloy Socket Weld Flanges/ SWRF flanges Flanges: Duplex, Super Duplex, Nickel Alloys

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Coating/Surface Treatment: Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Value Added Services: CNC Machining, Customised Flanges

GB9112-9131,SH3406,ANSI B16.5 ,DIN25762766,DIN2632-2638

from 150lbs to 2,500lbs.

DN10-DN800.

Carbon steel, stainless steel and alloy steel.

Carbon steel and alloy steel with yellow print, black print, oil or zinc.

Forged.

Dimension of Stainless Steel Socket Weld Flange

Manufacturer & supplier of Mild Steel Socket Weld Pipe Flanges and Galvanized Gi Socket Welded Flanges in Class 150#, 300#, 400#, 600#, 900#, 1500# and 2500# according to ANSI/ ASA/ ASME B16.5

ANSI B16.5

Class 150lbs, Class 300lbs

Class 600lbs, Class 1500lb

Socket Weld Flange ANSI Standards

ANSI :ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

Din standards of Raised Face Socket Weld Flange

Manufacturer of Ductile Iron Socket Welding Flange and Aluminum Socket Weld Orifice Flange in India, get a free quote, high quality A182 F11 Alloy Steel Socket Weld Rtj Flange at best price in Mumbai

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

Flat Face Socket Weld Flange BS Standards

B.S : BS4504 , BS4504, BS1560, BS10

Class 150 Socket Neck Flange Dimensions

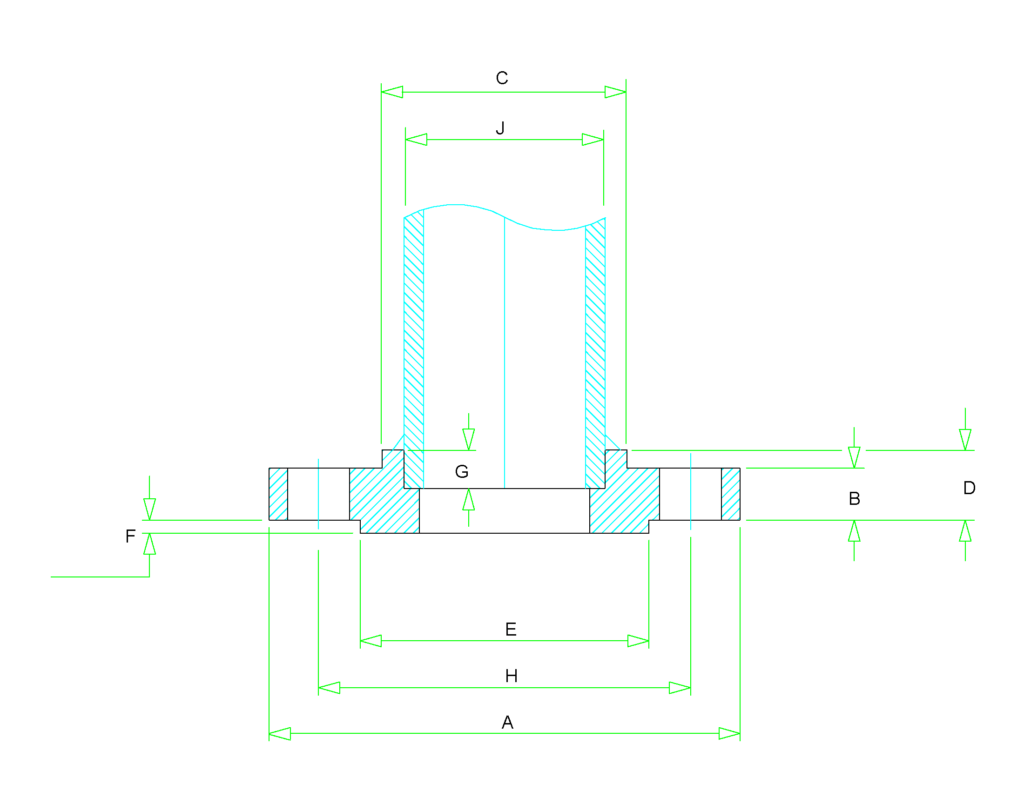

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | Socket Depth | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | |||||||||

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 10 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 11 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 13 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 14 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 16 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 17 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 105 | 2 | 19 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 21 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

Class 300 Socket Neck Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | Socket Depth | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | |||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21 | 34.9 | 2 | 10 | 66.7 | 22.2 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 14.3 | 48 | 24 | 42.9 | 2 | 11 | 82.6 | 27.7 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 54 | 25 | 50.8 | 2 | 13 | 88.9 | 34.5 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 25 | 63.5 | 2 | 14 | 98.4 | 43.2 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 29 | 73 | 2 | 16 | 114.3 | 49.5 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 84 | 32 | 92.1 | 2 | 17 | 127 | 61.9 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 37 | 105 | 2 | 19 | 149.2 | 74.6 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 27 | 117 | 41 | 127 | 2 | 21 | 168.3 | 90.7 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

Class 600 Socket Neck Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | Socket Depth | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 10 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 11 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 13 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 14 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 16 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 17 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 105 | 7 | 19 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 21 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

Class 1500 Socket Neck Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | Socket Depth | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 10 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 11 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 13 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.7 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 14 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 16 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 17 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 9.8 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 105 | 7 | 19 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.4 |

| 3 | 80 | 265 | 47.7 | 133 | N/A | 127 | 7 | 203.2 | N/A | 8 | 1 1/8 | 180 |