Products on sale

UNS NO6601 weldolet nickel alloy steel inconel 600 weldolet

描述

Olets are known as branch connection fittings used to provide an outlet from a larger pipe to a smaller one.

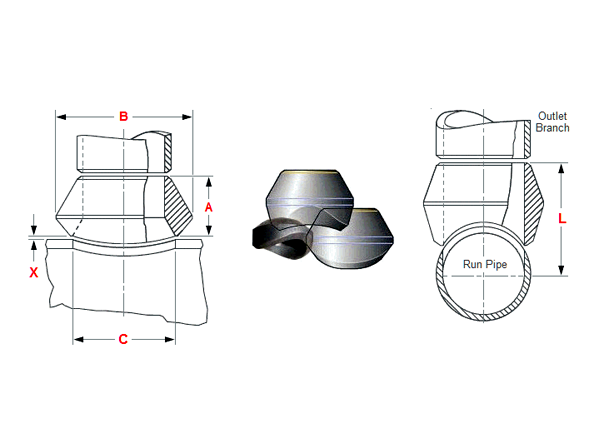

The primary pipe onto which the branch association is welded is generally called the Run or Header estimate. The pipe to which the branch association gives a channel is normally called the Branch or Outlet measure. Welded Outletsis an economical butt-weld branch connection, is considered to reduce stress concentrations and provide integral reinforcement manufactured according to the requirements of the clients.

Olets are known as branch connection fittings used to provide an outlet from a larger pipe to a smaller one. The primary pipe onto which the branch association is welded is generally called the Run or Header estimate. The pipe to which the branch association gives a channel is normally called the Branch or Outlet measure. Welded Outletsis an

Welded Outlets that are extensively used in various industry applications available in several size, grades, dimensions and grades in all materials such as stainless steel, duplex steel, alloy steel and carbon steel. The offered product are appreciated in the market because of the best performance and good quality of the products.

Features of Welded Outlets:

Abrasion resistance

Corrosion resistance

Durability

Dimensional accuracy

SPECIFICATION – ASTM A105 WELDED OUTLETS

WELDED OUTLETS

Size: 1/2″NB TO 24″NB IN

Class: 3000 LBS, 6000 LBS, 9000 LBS & Required Schedule

Materials: Stainless Steel Welded Outlets– SS Welded Outlets

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Duplex Steel Welded Outlets

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Alloy Steel Welded Outlets– AS Welded Outlets

ASTM / ASME A/SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel Welded Outlets– CS Welded Outlets

ASTMA 105/A694/ Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel Welded Outlets– LTCS Welded Outlets

A350 LF3/A350 LF2

Value Added Service: Hot Dip Galvanizing

Electro polish

DIMENSION – WELDED OUTLETS® SIZE ON SIZE -STD- MSS SP97

Dimensions NPS 1/2 to 24

Dimensions NPS 1/2 to 24

| NPS | A | B | C | D |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Dimensions: Top Row in Inches / Bottom Row in millimeters.

Root Gap – X – “Space” for welding the O’let is raised off the run pipe to establish proper weld gap by placing spacers, e.g. welding rods, under the fitting. This provides a uniform welding gap between the curvature of the run and base of fitting.

L = Dimensions Center Line of Run Pipe + X (Root Gap) + A (height of Welded Outlets).

Bevelled Ends ASME B16.9 and B16.25.

Source comes from Bonney Forge (except the sizes in millimeters).

Welded Outlets® is a registered name. Another often used name is Welding Outlet.

Other Diameters

NPS 1/2 – 24 STD Size on Size NPS 1/2 – 24 XS Size on Size NPS 3/4 – 20 STD Reducing NPS 3/4 – 20 XS Reducing

MARKING AND PACKING

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All olets are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

QUALITY ASSURANCE

all fittings and olets are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

TEST CERTIFICATES

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

SHIPPING POLICY

Delivery time and delivery dates are based on the “type and quantity” of steel ordered. Our sales team will provide a delivery schedule when quoting to you. On rare occasions the delivery schedule may change so please check with our sales department when placing any orders.

Orders will be sent out within 2-3 business days, and may take up to 5-10 business days in transit. If Olets is out of stock, orders may take up to 2-4 weeks to ship.

Chemical Oil Mills Petrochemical Mining Refineries Construction

Fertilizers Shipbuilding Power Plant Steel Plant Nuclear Power Offshore

Oil & Gas Defence Paper Ports Breweries Railway

Cement Engineering Co. Sugar & Government Org. etc.